What customers say

Description

Food Grade Silicone Rubber for Mold Making

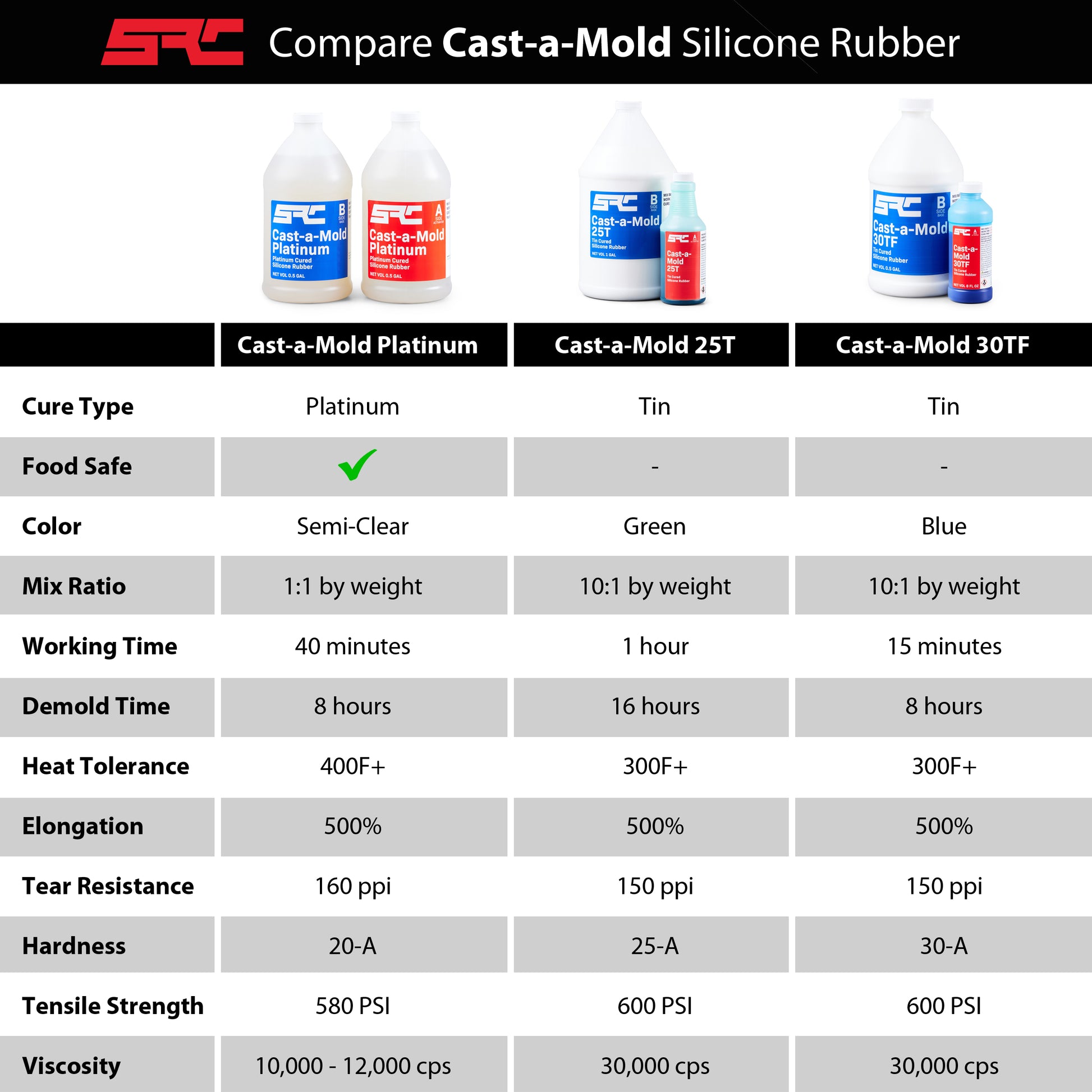

Cast-A-Mold Platinum is a versatile food grade platinum (addition) cured silicone rubber designed for a wide variety of mold making applications. It offers exceptional performance with its 1:1 mix ratio (by weight), low viscosity, excellent tear strength, tensile strength, elongation, heat deflection, and long silicone mold library life.

Custom Mold Applications:

The project possibilities for Cast-a-Mold Platinum go far beyond crafting custom resin molds. It can be used to make translucent silicone molds for variety of projects, such as:

- Casting candies and chocolates

- Cake decorating

- Casting polyurethanes

- Epoxy resin casting

- Polyester resin casting

- Cement

- Concrete

- Soap making

- Candle making (and other wax applications)

- Plaster

and many more!

Cast-A-Mold Platinum molding silicone is user friendly and FDA compliant, ensuring safe use in food-related applications. Another advantage is its ability to cure at room temperature, eliminating the need for specialized equipment or vacuum chambers.

Cast-A-Mold Platinum Notes and Tips:

Platinum cured silicone rubber can be heat accelerated. For instance, if you expose the mold to a temperature of 150°F (65°C), the curing time will be significantly reduced from 8 hours to just 30 minutes.

It's important to note that for food applications, it is recommended to wash the cured mold with warm water and soap before using it to ensure cleanliness and hygienic standards.

Addition-cure silicone rubber may be affected by certain contaminants, which can lead to tackiness on the surface of the mold. To avoid this, it's best to steer clear of materials like latex, sulfur-based clays, tin cured silicone rubber, amines, nitriles, and organo-metallic salt-containing compounds. If you're uncertain about the compatibility of the substrate being molded, it's always a good practice to conduct a small compatibility test beforehand. Additionally, applying a clear acrylic lacquer or paint on the pattern can help prevent inhibition. However, polyurethane and latex should not be used in this context.

Cast-A-Mold Platinum is comparable to Smooth-on Mold Star™, Smooth-Sil™, SORTA-Clear™, Ecoflex™ and Dragon Skin™ silicones.

Specifications

Specifications

| Mix Ratio | 1:1 by weight |

| Working Time | 40.0 minutes |

| Demold Time | 8.0 hours |

| Heat Tolerance | 400°F + |

| Tensile Strength | 580 psi |

| Elongation | 500% |

| Tear Resistance | 160ppi |

| Color | Semi-clear |

| Hardness | 20-A |

| Viscosity | 10,000 - 12,000 cps |